Introduction:

The Rise of Digital Twins in Modern Industry

In the era of Industry 4.0, businesses are increasingly turning to advanced modeling techniques to optimize processes, predict failures, and enhance efficiency. Two key technologies—Digital Twin and Traditional Simulation—are often discussed, but how do they differ, and when should each be used?

While traditional simulations have been the backbone of engineering and design for decades, digital twins represent a more dynamic, real-time approach. As someone with [Your Expertise/Experience], I’ve seen firsthand how companies leverage these tools—sometimes even together—to drive innovation. This article breaks down their differences, use cases, and real-world applications to help you decide which solution fits your needs.

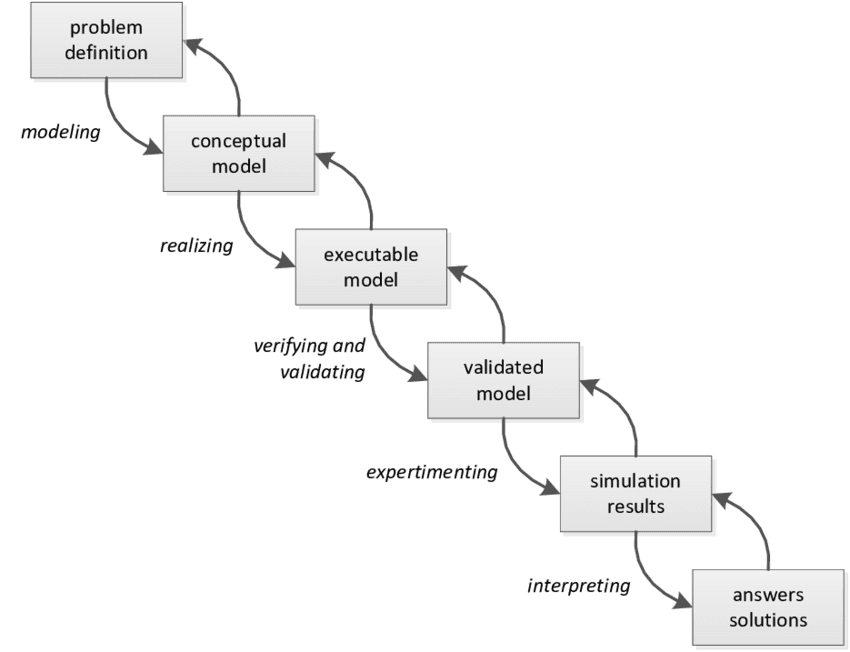

Defining the Basics: What Is Traditional Simulation?

Traditional simulation involves creating a static, mathematical model of a system to predict its behavior under specific conditions. These models are typically:

- Offline & Predefined: Simulations run in controlled environments based on fixed inputs.

- Scenario-Based: Used for testing “what-if” situations (e.g., stress-testing a bridge design).

- Deterministic: Outputs depend solely on initial parameters without live updates.

Example: Finite Element Analysis (FEA) in aerospace engineering simulates how an aircraft wing behaves under turbulence—but only for the exact conditions programmed.

What Is a Digital Twin? A Real-Time Virtual Mirror

A Digital Twin goes beyond static simulation by creating a live, data-driven replica of a physical asset, process, or system. Key characteristics include:

- Real-Time Data Integration: Uses IoT sensors, AI, and cloud computing to update continuously.

- Two-Way Interaction: Can both receive live data and send commands back to the physical system.

- Predictive & Adaptive: Learns from operational data to forecast failures or optimize performance.

- Case Study: General Electric uses digital twins for jet engines, where live sensor data predicts maintenance needs before failures occur—reducing downtime by up to 30%.

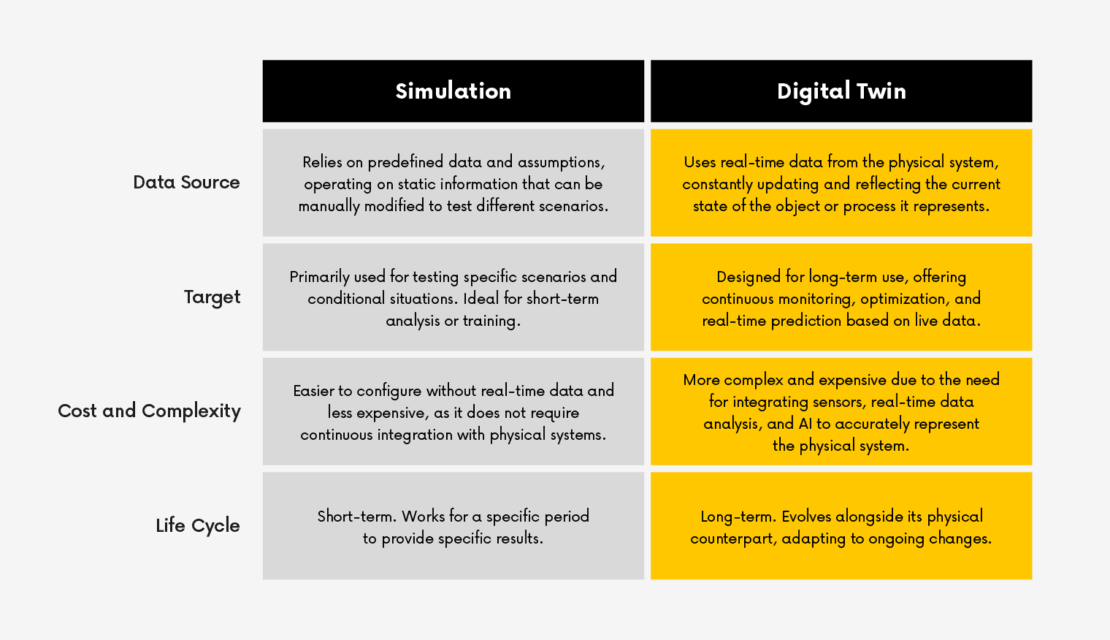

Key Differences: Digital Twin vs. Traditional Simulation

| Feature | Traditional Simulation | Digital Twin |

| Data Input | Static, predefined parameters | Dynamic, real-time IoT feeds |

| Updates | Manual reruns required | Continuous, automatic |

| Use Case | Theoretical analysis | Operational monitoring & control |

| Complexity | Limited to modeled scenarios | Evolves with system behavior |

Expert Insight: While simulations excel in design phases (e.g., prototyping a car’s aerodynamics), digital twins shine in operational phases (e.g., monitoring a smart factory’s production line).

When to Use Traditional Simulation

Traditional simulations are ideal for:

- Early-Stage Design – Testing hypothetical scenarios before physical prototypes exist.

- Example: Crash-test simulations in automotive engineering.

- Cost-Effective Modeling – When real-time data isn’t available or necessary.

Example: Simulating fluid dynamics for a new HVAC system.

Limitation: Simulations can’t account for unpredictable real-world variables like wear-and-tear or environmental changes.

When to Use a Digital Twin

Digital twins are superior for:

- Predictive Maintenance – Identifying equipment failures before they happen.

- Example: Siemens’ wind turbine twins optimize performance based on weather data.

- Live System Optimization – Adjusting processes in real time (e.g., smart cities managing traffic flow).

- Training & AI Development – Providing a sandbox for machine learning models.

Challenge: Requires robust IoT infrastructure and data pipelines, which can be resource-intensive.

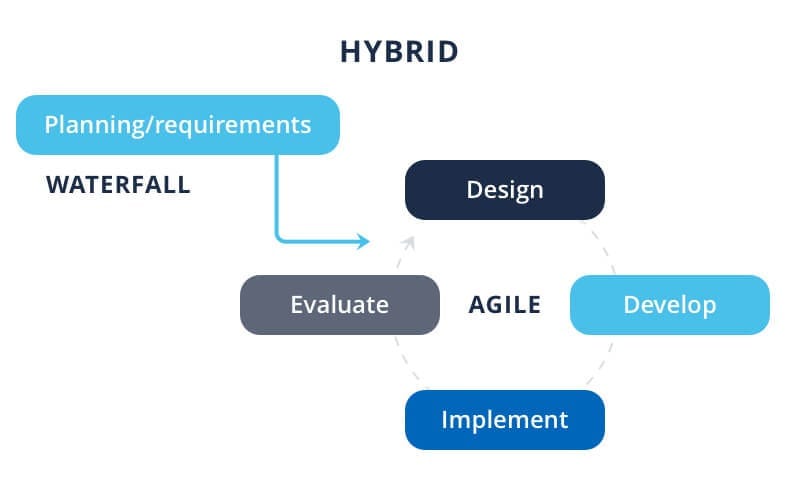

Hybrid Approaches: Combining Both Technologies

In many cases, the best solution integrates both:

- Phase 1 (Design): Use simulations to validate concepts.

- Phase 2 (Operation): Deploy a digital twin for ongoing management.

Real-World Example: NASA combines simulations for spacecraft design with digital twins to monitor missions like the Perseverance rover, adjusting strategies based on Martian conditions.

Conclusion: Choosing the Right Tool for the Job

While traditional simulations and digital twins share similarities, their applications differ significantly:

- Simulations are your go-to for theoretical, cost-efficient modeling.

- Digital Twins excel in live environments where real-time adaptability is critical.

As industries embrace IoT and AI, digital twins will become ubiquitous—but simulations will remain vital for foundational engineering. The key is understanding which tool (or combination) aligns with your project’s lifecycle.

Final Thought: Are you using simulations, digital twins, or both? Share your experiences in the comments!

Hello there! I could have sworn I’ve been to this website before but after browsing through some

of the post I realized it’s new to me. Nonetheless, I’m definitely happy I found it and

I’ll be bookmarking and checking back often!